Factory for the manufacturing of machines for food production

&

Factory for the manufacturing of Supersolar (PV) at a good price

Contribution for hunger aid and green energy

With the following two projects we can produce food and solar power with low pricing for installations in emerging and developing countries as well as industrial countries.

The complete project package is meant to be a humanitarian service to supply people with low-priced food, energy and labour (150 own and some thousand workers for preparations and follow-up works)

This package has a return of investment of 2 years in Germany

Leading worldwide and expendable to a billion market within a few years

There is a fusion of two factories planned for the production of food powder out of agricultural products like fruits, mushrooms, berries, herbs, vegetables etc. combined with solar power and an according solar factory for the manufacturing of high performance PV.

Hunger aid: Due to the subsidized, low-priced and healthy food powder as well as solar power

Project 1:

Food container are manufactured in a special factory for the production of food powder out of food surpluses like potatoes, corn, herbs and other crops, fruits, vegetables, even fish, milk and other perishable food.

There are some food powder mnufacturer, but not for the whole variety of agricultural products which we can generate really profitable.

Currently we can produce food powder out of more than 100 different agricultural products.

This system is up and running in six different locations in poland and other eastern european countries

Examples: Red Beet, carrots, cabbage, apples, pumpkins, zucchini, chokeberries, grapes, garlic

Further powders of different kinds are possible

Advantages:

- Production of baby food like milk powder etc.

- Our production process does not destroy the food cell systems like other competitors due to our careful processing chain below 60░ Celsius

- Aimed and very gentle procedures

- The produced food powders have an expiry date of 2-3 years and is therefore low-priced in logistics (ship delivery instead of planes etc.)

- No cold storages / cold containers needed

- 8-10 times less storage / weight capazities needed than perishable products

- Huge reserves of food possible

- Pulverize agricultural surpluses rather than destroying it

- Low-priced raw material input

- High concentrated food powder chkonzentriertes Lebensmittelpulver without harmful chemical additives

- Liquid surplus from the process of pressing can be used as drinking

- Extremely low-priced international supply with food for people and animals

One huge chance for the agricultural sector worldwide!

The manufactured food containers can be supplied with power directly on the field due to our specialised solar moduls below.

Project 2:

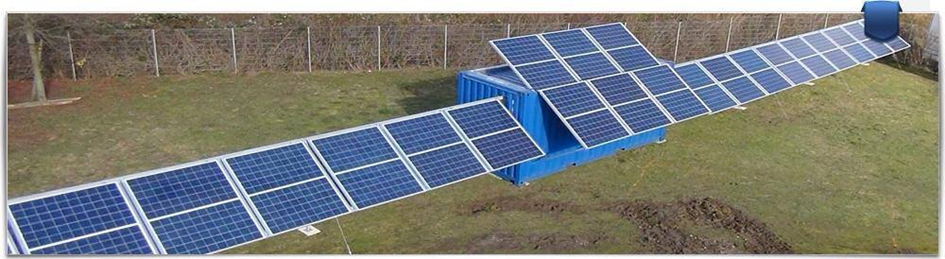

Food container with solar power

Food container with solar power

Factory for the manufacturing of photovoltaic solar with 50% more power supply line than competitors.

For the power supply of food containers directly on the field.

Export of the solar moduls in sunny countries as well as expansion of own super solar power plants of the next generation for worldwide leadership

Factor capacity: 90 MW per year

Advantages:

- 50 % better power supply line from high performance moduls (360-375 Watt per modul)

- 50 % reduced land and roof area consumption

- Low assembly costs

- Reduced raw materials used with a simultaneous higher power yield

- Worldwide unique advantages as the most effective and environment friendly energy source

- Pays off faster than wind or bio energy or the current standard solar

Therefore an unique selling point on the market regarding high performance solar

Capital requirements (Euro): 15 Mio. € or more per factory

including raw materials for two months.

Project 1: Factory for food powder: 15 Mio. €

Porject 2: Super solar factory: 15 Mio. €

Total for 2 factories : 30 Mio. € turn key

Return of investment: 2 – 3 years

Both products are ready for series production due to the longstanding preliminary work of two experts teams. Prototypes are existing and tested. Expert opinions, some patents, studies, lab tests are available already.

There are further teams/governments/foundation interested parties for this project package, who wants to transpose these packages in their own countries.

The projects can start instantly.

If interested, please request our detailled exposÚ.

Valid are the general terms and conditions of www.tha-germany.de

02/2017

|

Fabriken & Maschinen |

Construction materials

- Cement plants, new - 3.000to and 6.000to - turnkey with financing offer

- Cement plant, NEW

Various factories

Generation of energy

Food industry

Medical devices